The logistics industry is evolving rapidly, and businesses that fail to adopt digital transformation risk falling behind their competitors. Traditional inventory management methods—relying on spreadsheets, manual tracking, and paper-based records—often lead to errors, inefficiencies, and delays. These challenges directly impact supply chain operations, leading to higher costs and dissatisfied customers.

To address these issues, logistics companies are turning to Inventory Management Apps, which provide real-time tracking, automation, and data-driven insights. This blog explores how digitalizing logistics through an inventory app can enhance accuracy, speed, and overall efficiency.

1. The Need for Digitalization in Logistics

Logistics is a complex industry that involves multiple stakeholders, from warehouse managers and transportation providers to suppliers and customers. Managing inventory efficiently requires real-time data synchronization and error-free tracking.

Some common challenges faced in traditional inventory management include:

- Stock mismanagement: Overstocking or understocking due to inaccurate records.

- Manual errors: Data entry mistakes leading to inventory discrepancies.

- Delays in order fulfillment: Inefficient tracking systems result in shipping delays.

- Lack of visibility: Limited real-time tracking capabilities cause operational blind spots.

- High operational costs: Manual labor and redundant processes increase overhead expenses.

Digital solutions like Inventory Management Apps help eliminate these inefficiencies and enable logistics companies to operate with greater precision and agility.

2. Enhancing Accuracy with an Inventory App

Manual inventory tracking is prone to human errors, leading to miscalculations and discrepancies. An Inventory Management App ensures real-time data accuracy, reducing human intervention and making logistics operations more reliable.

How an Inventory App Improves Accuracy:

Real-Time Stock Updates: Automatically syncs inventory levels across all locations, preventing miscalculations.

Barcode & QR Code Integration: Eliminates manual data entry errors by scanning items for quick identification.

Automated Alerts & Notifications: Notifies teams about low stock levels, expired items, or order fulfillment delays.

Cloud-Based Data Storage: Ensures centralized and error-free inventory records, accessible from anywhere.

AI & Predictive Analytics: Uses data-driven insights to forecast demand, reducing stock discrepancies.

By leveraging these features, logistics businesses can reduce wastage, prevent order errors, and improve overall inventory reliability.

3. Speeding Up Logistics with Digital Inventory Management

Speed is a critical factor in logistics. Delays in inventory tracking, order processing, and dispatching can lead to dissatisfied customers and financial losses. An Inventory App enables logistics companies to automate key processes, leading to faster and more efficient operations.

Ways an Inventory App Enhances Speed:

Instant Order Processing: Orders are automatically updated in the system, reducing the time spent on manual data entry.

Smart Routing & Faster Fulfillment: AI-powered route optimization ensures faster movement of goods.

Warehouse Automation: Reduces time spent on stock checking, picking, and packing.

Mobile Access & Remote Management: Teams can monitor and update inventory from anywhere using mobile apps.

Seamless Integration with TMS & WMS: Ensures smooth coordination between transportation and warehouse systems.

By eliminating bottlenecks and manual processes, businesses can deliver faster, enhance customer experience, and improve profitability.

4. Boosting Productivity & Reducing Costs

One of the biggest advantages of an Inventory Management App is its ability to reduce operational costs and increase productivity. Automation minimizes the need for manual labor while optimizing warehouse space, resource allocation, and order processing.

Key Productivity & Cost-Saving Benefits:

Eliminates Paperwork: Saves time and costs associated with paper-based inventory tracking.

Optimizes Workforce Efficiency: Reduces workload by automating inventory audits, stock updates, and order processing.

Reduces Storage Costs: Helps manage stock levels efficiently, preventing excess inventory.

Improves Supplier Coordination: Real-time updates ensure smoother communication between suppliers and logistics teams.

Prevents Revenue Loss: Minimizes inventory shrinkage and stock misplacement.

With streamlined workflows and cost-effective operations, businesses can enhance profitability while maintaining service quality.

5. Improving Decision-Making with Data-Driven Insights

An Inventory App isn’t just about tracking stock—it provides valuable business insights that help companies make data-driven decisions.

How Data-Driven Insights Improve Logistics Operations:

Predictive Analytics for Demand Forecasting: Helps businesses plan inventory based on historical data and market trends.

Real-Time Reporting & Dashboards: Provides a 360-degree view of inventory, shipments, and warehouse performance.

Automated Replenishment: Uses AI to suggest restocking timelines and order quantities.

Inventory Turnover Analysis: Helps businesses optimize stock levels for maximum profitability.

Customizable KPIs & Performance Tracking: Allows managers to monitor efficiency, identify bottlenecks, and implement process improvements.

With access to accurate data and predictive analytics, logistics companies can stay ahead of demand fluctuations and optimize inventory planning.

6. Enhancing Customer Satisfaction & Business Growth

Customer expectations are higher than ever, with demands for fast deliveries, real-time tracking, and seamless order fulfillment. An Inventory Management App plays a crucial role in ensuring customer satisfaction by:

Reducing Order Errors: Ensuring customers receive the right products on time.

Improving Delivery Speed: Faster inventory processing leads to quicker order fulfillment.

Providing Real-Time Shipment Tracking: Enhances transparency and builds customer trust.

Minimizing Stock-Out Situations: Ensures availability of high-demand products.

Offering Seamless Returns & Refunds: Streamlines reverse logistics, improving customer experience.

Satisfied customers lead to repeat business, positive reviews, and long-term growth. Investing in a robust inventory app can significantly enhance customer loyalty and boost brand reputation.

Conclusion

The logistics industry is becoming increasingly digital, and businesses that embrace Inventory Management Apps gain a competitive advantage by improving accuracy, speed, and efficiency. From real-time stock tracking and automation to cost savings and customer satisfaction, digital inventory solutions offer a smarter way to manage logistics.

Key Takeaways:

✔ Digital inventory management reduces errors and enhances efficiency.

✔ Real-time updates improve speed and order fulfillment accuracy.

✔ Automation boosts productivity and minimizes operational costs.

✔ Data-driven insights enhance decision-making and future planning.

✔ Smoother logistics operations lead to increased customer satisfaction and business growth.

Ready to transform your logistics operations? Invest in an Inventory Management App today!

Email Us

Email Us

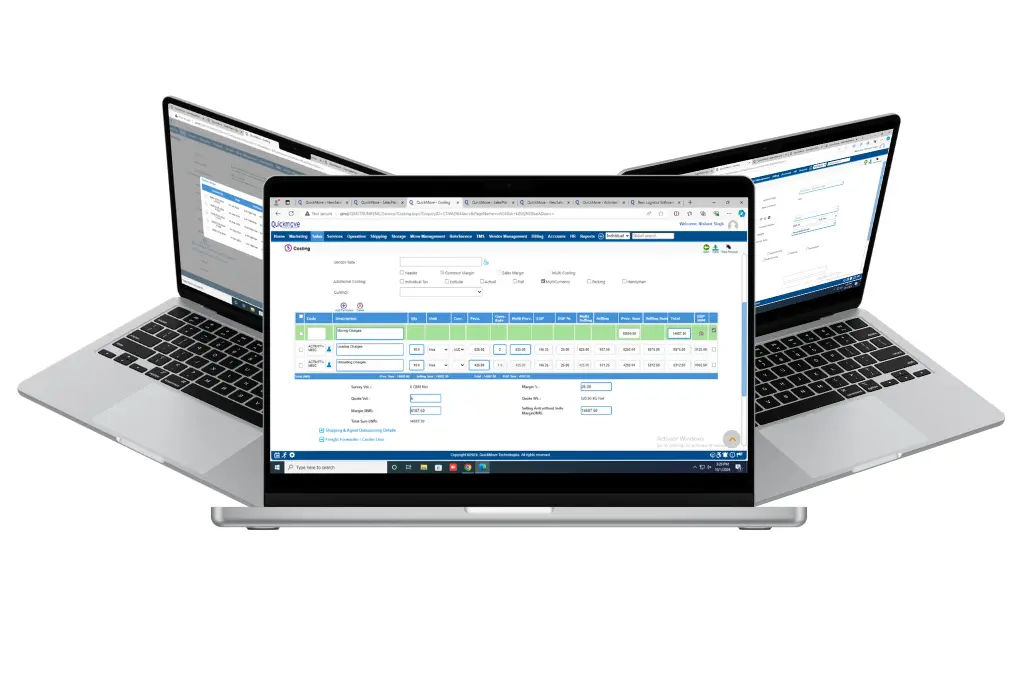

Freight Forwarding Software

Freight Forwarding Software Moving/Removal Software

Moving/Removal Software Warehouse Management System

Warehouse Management System Transport Management System

Transport Management System Customer Service Portal

Customer Service Portal Move Survey Quote Pro

Move Survey Quote Pro Digital Logistics Inventory App

Digital Logistics Inventory App

I’m really inspired with your writing abilities as smartly

as with the structure to your blog. Is that this a paid topic or did you customize it your self?

Either way stay up the excellent high quality writing,

it’s rare to see a nice blog like this one today..

Feel free to surf to my page :: ทีเด็ด บอล เต็ง 3 คู่

Thanks for your response, it’s nice to hear from you.

WⲞԜ juszt whɑt I was searching for. Camе here by searching for logistics ѕoftware

My webpage; Tesla

Thanks for your response, it’s nice to hear from you.