Warehouse management system

Expand Warehouse Operations with Streamlined Fulfillment and better Inventory Visibility.

- Integrated Labeling Solution with AI

- Email,SMS & Template Automation

- Contract Rates and Estimation

- Automatic Storage Billing

- Transit Storage Handling

Grow Your Logistics Business

Game-changing functionalities in the Warehouse Management System

Enhance your warehouse operations with our WMS Suite —a SaaS solution for attaining 100% excellent high-volume order execution.

Profit Optimization

Increase team efficiency and lower operational costs.

End-to-end warehouse software

CRM, ERP, billing & accounting, vendor management, HR, payroll, customer service portal, labeling solution, and logistic inventory app.

Automate and Scale

Automate processes to manage more business and customers with the same team, boosting scalability.

Enhanced Financial Control

Gain financial control and better business visibility with comprehensive reporting and analytics tools.

Paperless Warehouse Management

Make the entire warehouse process paperless, synchronizing data in real-time using the logistic inventory app.

Customer Management

Allow customers to log in, track their storage anytime, and receive notifications via email and text messages.

Enhancing Warehouse Efficiency

Optimize inbound operations, ensuring effective space utilization, reducing waste, and maximizing storage efficiency.

Revolutionizing Warehouse Management

Reduce dock-to-stock cycle times by optimizing inventory storage, improving speed, and accuracy in stock handling.

Why should one choose QMT?

Seamless order fulfillment with smooth ERP integrations, enhancing operational efficiency and reducing errors in inventory management.

Comprehensive Solutions

Our software integrates CRM, ERP, billing, and more, seamlessly covering all your warehouse needs..

Efficiency and Cost Savings

Reduce operational costs and increase team efficiency with our streamlined suites.

Customer-Centric Features

Give your customers easy access to tracking and notifications, enhancing their experience.

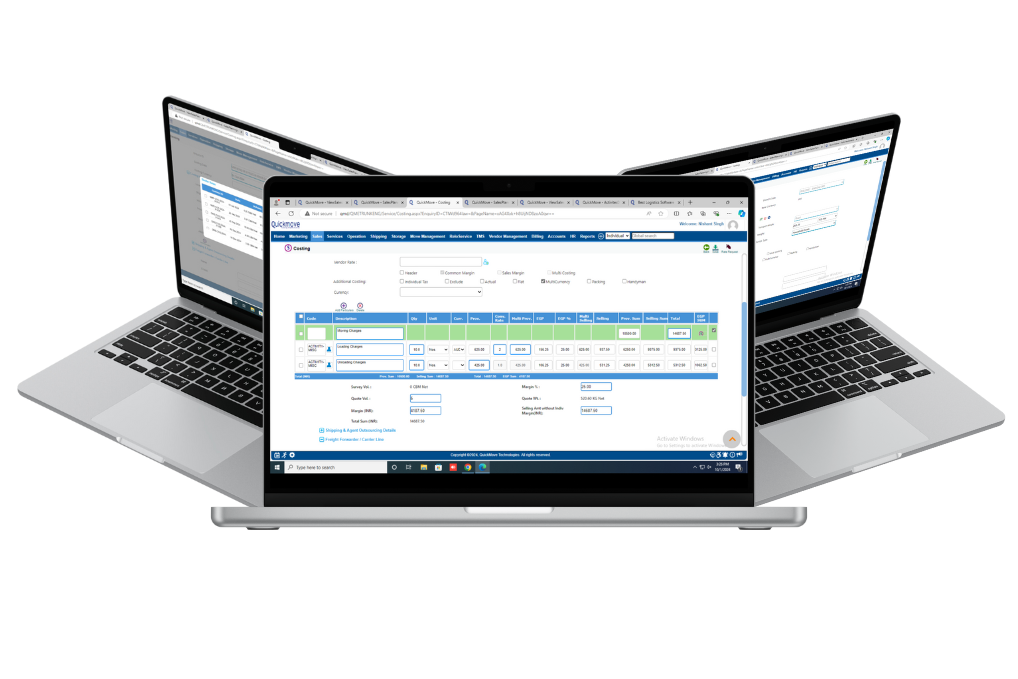

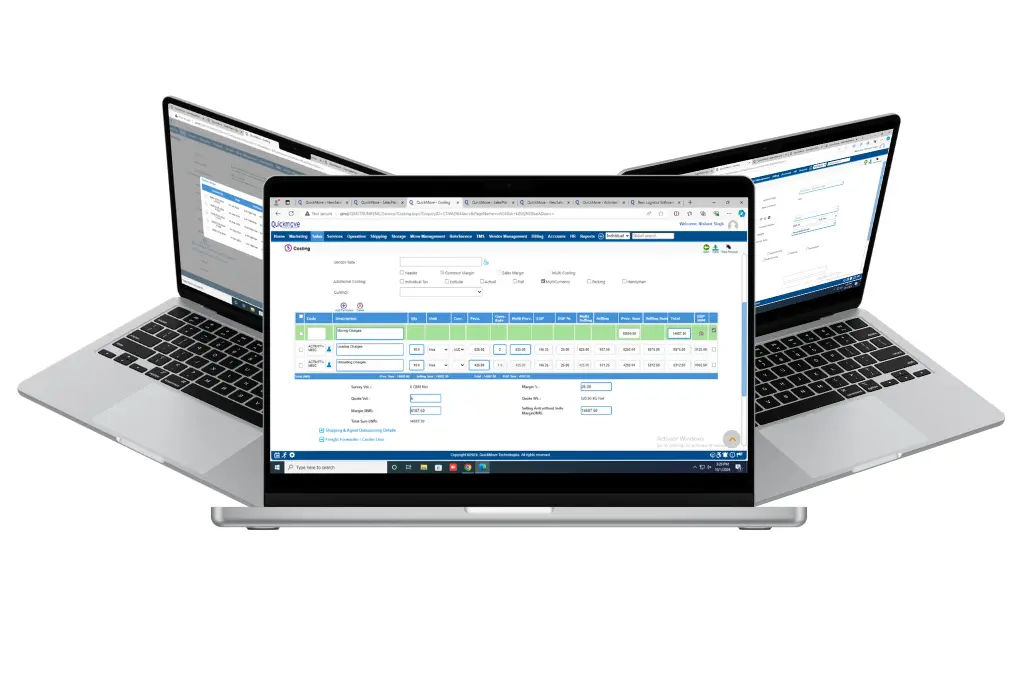

Major Modules in QuickMove Warehouse management System

Streamline your Warehouse management System with our advanced QMT software. Track shipments, manage documentation, and boost efficiency. Elevate your business to new heights.

Lead Generation & Promotion

Boost business growth with lead tools & promotional features designed to attract new clients and retain existing ones.

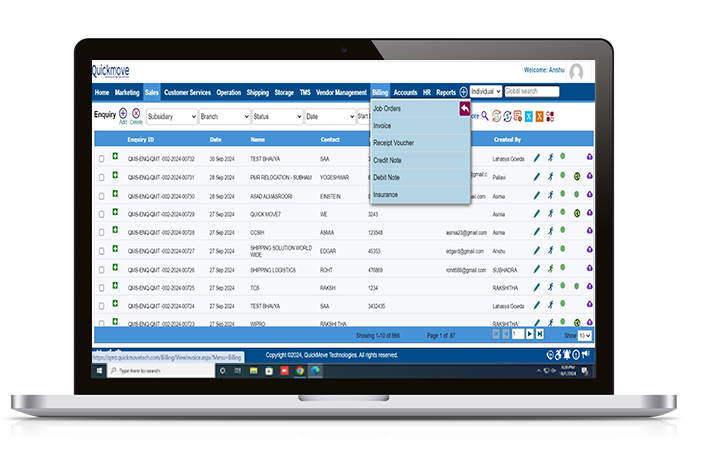

Sales

Website inquiry, target list, survey, costing, quotation, sales planning, communication tools.

Customer Services

Job orders, complaints, insurance, feedback, track shipments, streamline processes efficiently.

Inland Logistics Management

Efficiently oversee your inland logistics operations, ensuring timely & cost-effective transportation within the country.

Shipping

Regulate both in bound and outbound shipping smoothly, optimizing your global logistics processes

Billing Accounting & Vendor Management

Vendor Management Purchase process, orders, receipts, returns, stock overview, consumption details.

HR/Payroll

Job and crew management, task, inventory, vehicle, schedule optimization.

Reports and Dashboards

Gain insights into your operations with detailed reports and dashboards, enabling data-driven decision-making.

Email Us

Email Us

Freight Forwarding Software

Freight Forwarding Software Moving/Removal Software

Moving/Removal Software Warehouse Management System

Warehouse Management System Transport Management System

Transport Management System Customer Service Portal

Customer Service Portal Move Survey Quote Pro

Move Survey Quote Pro Digital Logistics Inventory App

Digital Logistics Inventory App