I. Introduction

Managing a warehouse comes with its fair share of challenges, from inventory optimization to accurate order fulfilment.

Fortunately, advancements in software technology have revolutionised the warehouse industry, offering innovative solutions that streamline operations and maximise efficiency.

II. Understanding Warehouse Management System (WMS)

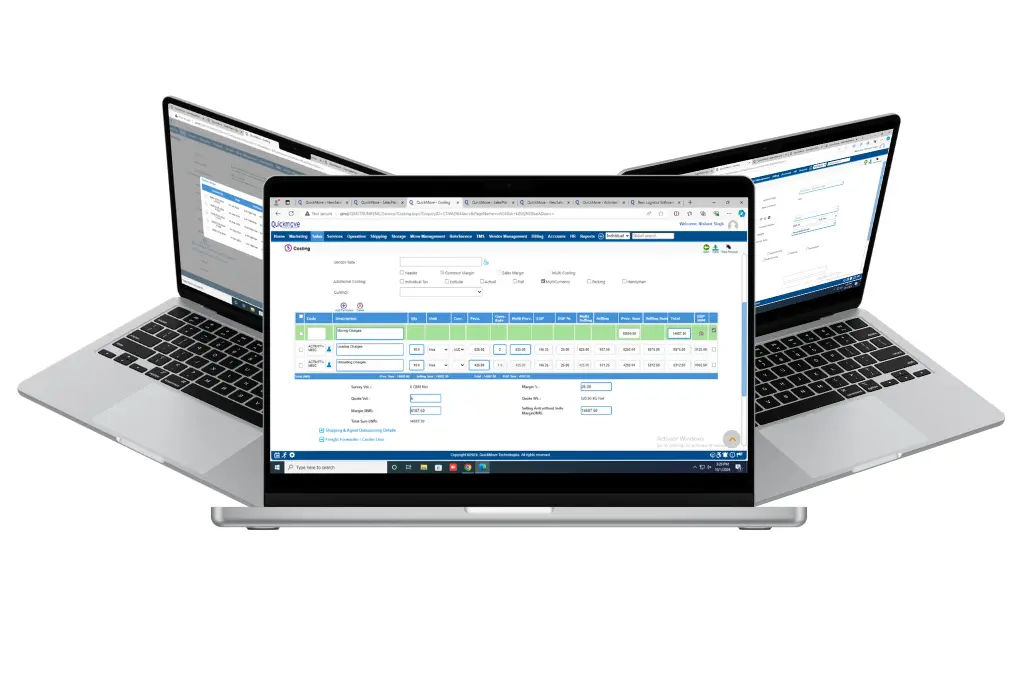

A Warehouse Management System (WMS) is a software solution designed to support and enhance warehouse operations. It encompasses various key features that contribute to the smooth functioning of warehouses.

Definition and Key Features of WMS

A WMS is a comprehensive software system that helps manage all aspects of warehouse operations.

Inventory Optimization

WMS software provides real-time insights into inventory positioning, allowing for better management of stock levels, reducing excess inventory, and increasing turnover efficiency.

Order Accuracy and Fulfilment

By automating order processing and tracking, WMS ensures that orders are picked accurately, packed securely, and delivered on time.

Labour Management

WMS software provides tools for labour planning, scheduling, and optimization, enabling businesses to allocate resources effectively and improve productivity.

Real-time Tracking and Visibility

With WMS software, warehouse managers have instant access to real-time data, providing visibility into inventory levels, order status, and overall warehouse operations.

Benefits of Implementing a WMS

Inventory Optimization

By providing accurate inventory data, WMS software enables businesses to reduce carrying costs, minimize stockouts, and improve overall supply chain efficiency.

Order Accuracy and Fulfillment

With WMS, businesses can achieve higher order accuracy rates, reducing customer complaints and improving customer satisfaction.

Labor Management

WMS software helps in optimizing labor resources, ensuring that the right people are assigned to the right tasks at the right time. This leads to improved productivity and reduced labor costs.

Real-time Tracking and Visibility

With Warehouse Management System (WMS) , businesses gain real-time visibility into their warehouse operations, allowing them to make informed decisions, identify bottlenecks, and take proactive measures to improve efficiency.

III. Exploring Different Types of Warehouse Management Software

There are different types of warehouse management software available, each catering to specific business needs and preferences.

Cloud-based WMS

Cloud-based WMS is hosted on remote servers, allowing businesses to access the software through an internet connection.

This type of WMS offers several benefits, including:

Scalability: Cloud-based WMS can easily scale operations up or down to accommodate fluctuating business needs, making it a flexible solution for growing businesses.

Cost savings: Cloud-based WMS eliminates the need for expensive hardware and maintenance, reducing upfront costs and ongoing IT expenses.

On-premises WMS

On-premises WMS, as the name suggests, is installed locally on the business’s own servers. While it requires upfront investment, it offers certain advantages:

Data control: With on-premises WMS, businesses have complete control over their data and can ensure its security.

Customization: On-premises WMS allows for more customization options, enabling businesses to tailor the system to their specific requirements.

Hybrid WMS

Hybrid WMS combines the benefits of both cloud-based and on-premises solutions. It offers flexibility, scalability, and ease of access like cloud-based WMS, while also providing the ability to store critical data on-site for added security.

IV. Key Features and Functionality of Warehouse Management System (WMS)

Warehouse Management Software provides a range of essential features that streamline warehouse operations and improve efficiency.

Inventory Management

Warehouse Management Software offers comprehensive inventory management capabilities, including:

Real-time tracking: WMS provides accurate inventory visibility, enabling businesses to track stock movements, monitor stock levels, and ensure timely replenishment.

Demand forecasting: WMS software uses historical data and advanced algorithms to forecast demand accurately, helping businesses optimize stock levels and reduce the risk of stockouts.

Real-time Tracking

One of the key features of WMS is real-time tracking, which allows businesses to monitor the movement and location of items within the warehouse in real-time. This significantly improves inventory accuracy, reduces search time, and minimizes errors.

Order Management and Fulfillment

WMS software streamlines order processing and fulfillment, ensuring timely and accurate delivery. Key features include:

Automated order processing: WMS automates order processing, reducing manual errors and improving order accuracy.

Order picking and packing optimization: WMS simplifies and optimizes the order picking and packing processes, reducing the time taken to fulfill orders.

Order Picking and Packing

Order picking, a crucial process in warehouses, is made more efficient with WMS. WMS software streamlines order picking by optimizing pick paths, assigning pick tasks based on proximity, and providing pickers with real-time instructions, reducing pick errors and increasing productivity.

Wave Planning and Optimization

WMS incorporates wave planning and optimization, a methodology that groups orders into waves based on factors such as priority, delivery location, and order size. This allows for efficient resource allocation, reduces travel time, and improves overall productivity.

Returns Management

Returns management is an essential part of warehouse operations. WMS facilitates returns processing by automating the entire returns workflow, ensuring that returns are efficiently handled, restocked, or returned to suppliers.

Labor Management and Optimization

WMS assists in labor planning and optimization by providing tools for resource allocation, task assignment, and performance tracking. It helps businesses reduce labor costs, improve productivity, and ensure optimal resource utilization.

Task Interleaving

Task interleaving is a feature of WMS that optimizes the sequence and combination of tasks performed by warehouse staff. By intelligently interleaving tasks such as picking, packing, and replenishment, WMS maximizes efficiency and minimizes travel time.

XII. Summary

Streamlining warehouse management is crucial for boosting efficiency and staying competitive in today’s fast-paced business environment. Innovative software solutions like Warehouse Management Software offer a range of benefits, from inventory optimization to real-time tracking and labor management. Embracing technology and implementing WMS can help businesses overcome warehouse management challenges, improve operational efficiency, and ensure future success.

XIII. FAQs (Frequently Asked Questions)

What are some signs that my warehouse needs management software?

Increased order errors and fulfillment delays.

Inaccurate inventory records.

Difficulty in tracking shipments and order status.

Inefficient utilization of labor resources.

How can warehouse management software help with inventory accuracy?

Warehouse management software provides real-time visibility and tracking of inventory, enabling businesses to maintain accurate inventory records, optimize stock levels, and reduce stockouts or excess inventory.

What security measures should be in place when using cloud-based warehouse management software?

When using cloud-based warehouse management software, it is important to ensure robust security measures such as data encryption, user access controls, regular data backups, and compliance with industry standards like ISO 27001.

Can Warehouse Management System (WMS) be customized to meet our specific business needs?

Yes, warehouse management software can be customized to align with your specific business needs, including tailored workflows, reports, and integrations with other business systems.

How long does it take to implement warehouse management software?

The implementation timeline for warehouse management software varies depending on the complexity of your warehouse operations and the scope of customization required. On average, it can take several weeks to a few months to fully implement and integrate the software into your existing systems.

Email Us

Email Us

Freight Forwarding Software

Freight Forwarding Software Moving/Removal Software

Moving/Removal Software Warehouse Management System

Warehouse Management System Transport Management System

Transport Management System Customer Service Portal

Customer Service Portal Move Survey Quote Pro

Move Survey Quote Pro Digital Logistics Inventory App

Digital Logistics Inventory App