Introduction

Embarking on the path of warehouse inventory management involves intricate maneuvers to track, store, and govern the ebb and flow of goods within a repository. A vital cog in the supply chain machinery, this discipline empowers businesses to enhance efficiency, foster profitability, and elevate customer contentment.

The Merits of Warehouse Inventory Management

Numerous gains emerge from proficient warehouse inventory management, notably:

Enhanced Efficiency:

Mastering warehouse inventory management bestows upon businesses the boon of streamlined warehouse operations. The ramifications include accelerated order processing, diminished labor costs, and curtailed inventory shrinkage.

Augmented Profitability:

A well-regulated warehouse inventory enables businesses to wield the optimal stock levels, ensuring seamless fulfillment of customer demands. The upshot comprises elevated sales figures and mitigated expenses.

Enriched Customer Satisfaction:

Satisfied customers are the lifeblood of a thriving enterprise. By prioritizing warehouse inventory management, businesses guarantee the prompt and complete delivery of orders, catalyzing repeat patronage and glowing word-of-mouth endorsements.

Categories of Warehouse Inventory Management Systems

The arsenal of warehouse inventory management systems comprises diverse categories, with some popular ones being.

Barcode Scanning Systems:

Employing barcodes for monitoring goods in and out of warehouses, this system bestows efficiency and error reduction in inventory tracking.

RFID Systems:

Harnessing radio frequency identification tags, this advanced system ensures unparalleled precision and efficiency in inventory management compared to barcode scanning.

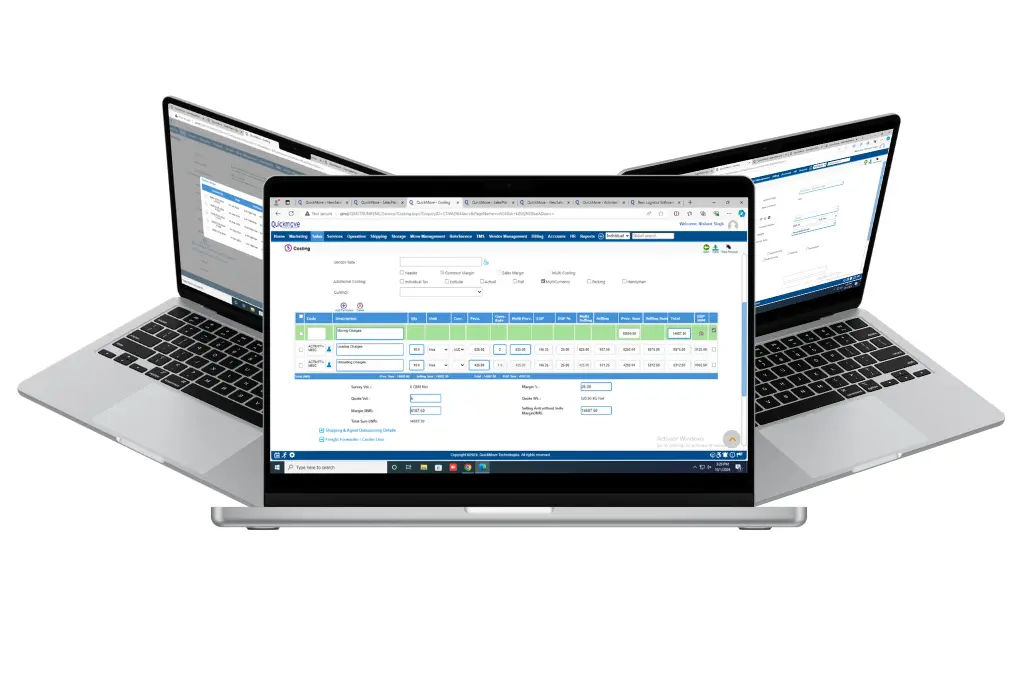

Warehouse Management System (WMS) :

A potent software application that enables comprehensive inventory tracking and management through multifarious features like barcode scanning, RFID integration, and order tracking.

The Steps Encompassing Warehouse Inventory Management

The trajectory of warehouse management system entails multifaceted steps, varying based on the system employed. However, some recurring steps encompass.

Receiving Inventory:

A meticulous process whereby incoming goods are verified and logged for quantity accuracy.

Storing Inventory:

Ensuring safe and accessible storage to preserve the integrity of the stock.

Tracking Inventory:

Real-time monitoring of inventory movements, lending clarity to the whereabouts of goods at all times.

Order Picking:

Prompt retrieval of orders from the warehouse, preparing them for seamless shipping.

Shipping Inventory:

Timely and efficient shipment of goods to awaiting customers.

Optimum Practices for Warehouse Inventory Management

Practicing excellence in warehouse inventory management calls for adherence to key tenets, including.

Embrace Barcode Scanning or RFID Systems:

Employ these state-of-the-art systems for precise and foolproof inventory tracking.

Establish Elaborate Inventory Database:

A comprehensive database enables vigilant monitoring and the prompt identification of potential issues.

Set Reorder Points: Strategically define stock reorder thresholds to match customer demand..

Conduct Regular Inventory Audits:

Periodic stock checks are vital to identify and rectify discrepancies in inventory records.

Implement Returns Management:

Streamlining the returns process to efficiently handle customer product returns.

Conclusion

Warehouse inventory management stands as an indomitable pillar in any supply chain apparatus. When businesses embrace the insights shared in this article, they can elevate their operational efficiency, bolster profitability, and kindle lasting customer delight. In closing, I trust this article has been a beacon of guidance on your journey. Should you seek further elucidation, do not hesitate to grace us with your queries in the comments section below.

Email Us

Email Us

Freight Forwarding Software

Freight Forwarding Software Moving/Removal Software

Moving/Removal Software Warehouse Management System

Warehouse Management System Transport Management System

Transport Management System Customer Service Portal

Customer Service Portal Move Survey Quote Pro

Move Survey Quote Pro Digital Logistics Inventory App

Digital Logistics Inventory App