The warehousing and logistics industry is the back bone of supply chain management, facilitating free flow of goods within and across countries but conventional warehousing tends to be plagued with inefficiency, late delivery, and inadequate inventory management. Enter real-time GPS tracking—a pioneering technology that’s transforming the future of the warehousing sector. With asset monitoring, process automation, and decision-making, real-time GPS tracking is leading the way in building smarter, more connected warehouses.

What Is Real-Time GPS Tracking?

Real-time GPS (Global Positioning System) tracking is a technology that offers second-by-second location information for objects, vehicles, or shipments. By fitting tracking devices with GPS on warehouse items such as inventory, pallets, and forklifts, organizations have the ability to monitor their location and movement in real time and gain unparalleled visibility across the supply chain.

The Advantages of Real-Time GPS Tracking in Warehouse

Implementing real-time GPS tracking on warehouse operations delivers a set of benefits in terms of efficiency, cost-effectiveness, and accuracy. This is how it’s revolutionizing the game:

1. Enhanced Inventory Management

Monitoring thousands—or millions—of stock items can be overwhelming. GPS tracking enables warehouse managers to determine the position of items with pinpoint accuracy, reducing search time for lost products. Not only does it speed up picking and packing but also reduces errors with the knowledge that orders are being delivered accurately.

For example, imagine a warehouse worker who needs to locate a specific pallet during a peak operations period. With real-time GPS tracking, they can quickly determine its location, preventing delays and improving productivity.

2. Enhanced Fleet Operations

For warehouses that use fleets of forklifts, trucks, and other vehicles, real-time GPS tracking offers important information about vehicle usage, efficiency, and routing. Managers can track the locations of vehicles, routes of travel can be optimized, and fuel consumption reduced. Operations become cheaper, and deliveries are completed in time.

GPS tracking can also identify underutilized vehicles, hence enabling organizations to be able to manage resources effectively.

3. Enhanced Asset Visibility

Real-time GPS tracking expands visibility beyond inventory—warehouse equipment such as forklifts, conveyors, and drones can be tracked as well. This makes sure that all equipment is being utilized effectively and is not stolen or used by unauthorized personnel. Having an idea of where all assets are at any point in time allows warehouses to optimize their assets.

4. Improved Worker Safety

Worker safety is a priority when it comes to warehousing, and GPS tracking is necessary for on-site safety. GPS tracking of vehicles and equipment helps alert workers to imminent danger and avoid accidents. Wearable GPS units also enable real-time location tracking of employees, allowing quicker response to emergencies in the event of accidents or injuries.

5. Minimized Downtime

Inefficiency in the warehouse usually originates from delays in loading, unloading, or equipment availability. With real-time GPS information, warehouses can anticipate bottlenecks and manage operations ahead of time, minimizing downtime. This allows for smoother operations and maintains timelines, especially in time-sensitive businesses such as e-commerce.

6. Data-Driven Decision-Making

Data captured by GPS tracking devices offers insights to warehouse managers. With an analysis of patterns and trends, organizations are able to identify areas of inefficiency, streamline workflow, and save on operating expenses. GPS tracking and predictive analytics can also be used to anticipate inventory requirements so that warehouses can be positioned effectively to cope with varying demand.

Major Applications of GPS Tracking in Warehouse

Cold Chain Logistics: In case of food and pharma industries, GPS tracking is used to maintain and transport temperature-sensitive items in the proper conditions.

E-Commerce Fulfillment: In e-commerce, speed is of the essence. GPS tracking supplements order picking, packing, and last-mile delivery.

Automated Warehouses: Integrated with robotics and IoT sensors, GPS tracking maximizes warehouse automation in a way that coordination among systems is seamless.

Third-Party Logistics (3PL): GPS tracking allows for improved coordination between third-party logistics providers and warehouses, introducing the transparency needed to clients and end users.

Adoption Delays and Challenges

Although there are rich rewards in real-time GPS tracking, its implementation is not without challenge. Installation fees for setting tracking systems and integrating them with existing WMS are high. Further, there is ample data that must be processed and analyzed by skilled staff and advanced analysis software.

But as technology improves and prices fall, more companies are embracing GPS tracking as a warehousing tool.

The Future of Warehouse

The coupling of real-time GPS tracking with other cutting-edge technologies such as AI, IoT, and robotics is defining the future of warehousing. Real-time information is becoming a significant component of today’s supply chain, bestowing companies with a competitive edge in the fast-moving world.

Conclusion

Real-time GPS tracking is no longer a luxury for warehousing operations—it’s a necessity. With its offer of increased visibility, security, and streamlined operations, real-time GPS tracking keeps businesses ahead of the competition while meeting customer needs. For businesses determined to streamline their logistics and gain an edge over the competition, investing in real-time GPS tracking is a move in the right direction.

Email Us

Email Us

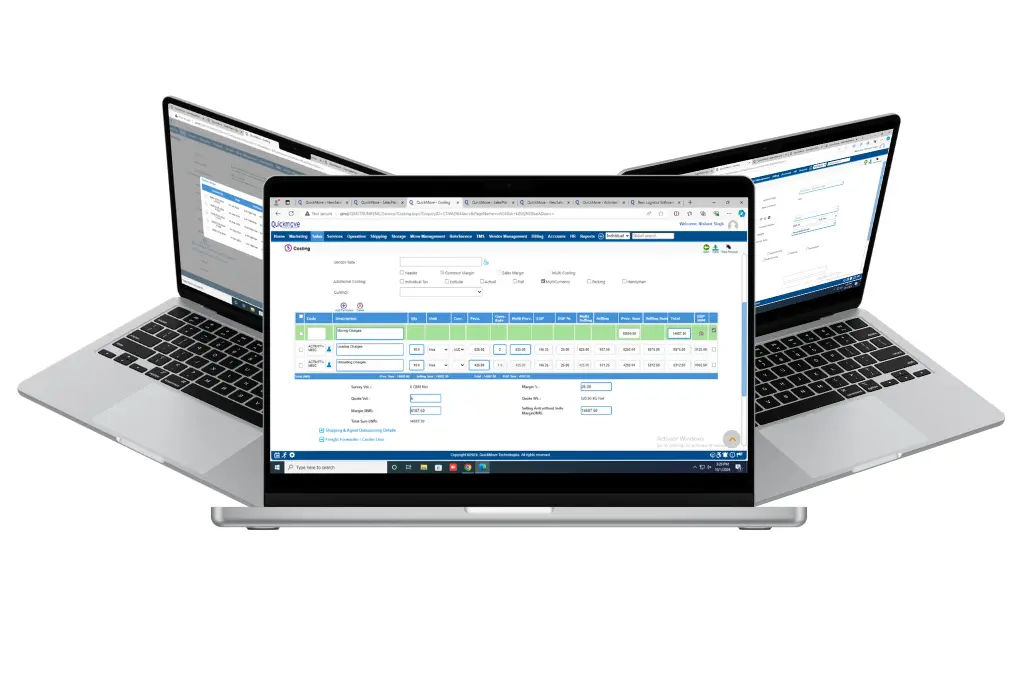

Freight Forwarding Software

Freight Forwarding Software Moving/Removal Software

Moving/Removal Software Warehouse Management System

Warehouse Management System Transport Management System

Transport Management System Customer Service Portal

Customer Service Portal Move Survey Quote Pro

Move Survey Quote Pro Digital Logistics Inventory App

Digital Logistics Inventory App