Whether you are managing a large distribution center or supervising a tiny warehouse, effective warehouse management is the lifeblood of logistics operations. Operational inefficiencies can result in bottlenecks, slower turnaround times, and lower profitability as business needs increase. Let’s start by using barcode and QR code integration—a proven technique transforming warehouse management systems (WMS).

These tools give a competitive advantage in an industry where seconds are critical by improving output, cutting human error, and simplifying inventory control. The blog will discuss how the use of barcode and QR code integration in WMS is transforming warehouse efficiency.

Knowing Warehouse Barcode & QR Code Technologies

Digital wonders, barcodes, and QR code technology have developed to be essential for warehouse work. Here are both broken down fast:

What Are Barcodes?

Machine-readable patterns consist of parallel lines and numbers, and barcodes encode information. Using a barcode scanner, these patterns may be scanned in seconds to get stock-keeping unit (SKU) data, product serial numbers, locations, or batch information.

What Are QR Codes?

QR (Quick Response) codes provide a two-dimensional option alternative to barcodes. In a small square format, they can store much more data—including text, URLs, and inventory information—than linear barcodes. Smartphones and advanced scanning equipment can scan QR codes, so they are flexible instruments in a warehouse setting.

In fast warehouses, real-time data entry from both systems reduces the need for manual recording and lessens the scope for errors, which is otherwise crucial.

Advantages of the use of barcode & QR code integration in WMS

Including QR code and barcode technologies in your warehouse management software has several benefits that can greatly increase output. This is the way it goes:

- Better inventory accuracy: – QR codes, along with barcodes, allow for instant, automatic data capture. This lowers the possibility of mistakes usually seen in manual data entry. Good stock control and reduced discrepancies result from exact inventory information.

- More Quick Order Processing: By quickly going through products for picking and packing operations, warehouse teams can significantly cut order processing times. This is especially important in sectors such as e-commerce, where consumer demand accelerated order fulfillment.

- Lower labor costs: Using these technologies, scanning barcodes or QR codes takes only seconds, therefore lowering the personnel needed for laborious manual audits and counting operations.

- Improved clarity: Allowing real-time data tracking, barcode, and QR code integration provides more openness across the supply chain. Managers have immediate access to information on stock quantities, product sources, and shipping conditions.

- Better tracking of assets: Every item or part in a warehouse can have a distinct barcode or QR code. This level of granularity allows for very exact asset tracking, therefore stopping loss or misplacement.

- Whether it can scale: Barcodes and QR codes scale guarantee that those systems grow with your company, whether you are running a little 200 SKU storage or a more sophisticated enterprise with thousands of SKUs.

How WMS enables barcode and QR code integration

Although integrating barcode and QR code technology into your WMS can seem challenging, current systems have simplified it. A step-by-step guide provided is presented here:

- Select your technology: Choose barcodes or QR codes. Barcodes are simple and cost-effective; QR codes have more sophisticated features, such as embedding URLs or more product information.

- Hardware Configuration: Integrate your WMS effortlessly with QR code readers or barcode scanners that you install. If your activities are not connected to industrial-grade scanners, modern mobile gadgets with scanning applications also work.

- Labeling/Tagging:- Tag all bins, pallets, or product categories in the warehouse with QR codes or barcodes. Guarantee labels meant to withstand tough warehouse environments last.

- Link with WMS:- Sync the scanners with your WMS to allow for real-time data entry and changes. Scanned data can be immediately seen in inventory records for more thorough control.

- Employee Training: Give employees simple guidance on how to operate barcode scanners, QR code readers, and the WMS interface. One must have a properly trained team in order to harness the efficiency advantages of these advancements.

- Keep track and iterate: Monitor post-implementation system performance and fix any technical problems or efficiency gaps. Constantly assess how well the system fits with your current procedures.

Case Study / Example of a Successful Barcode & QR Code Integration in Warehousing:

Case study overview:

Based in California, a midsize e-commerce company fought with slow order fulfillment procedures and inventory errors, which stole time and money. They chose to incorporate their WMS with QR codes.

Results:

- Warehouse productivity grew by 35% after application.

- From 85 percent to 99.5, order accuracy improved.

- With less manual correction work, labor costs dropped 20%.

- Daily pick and pack speeds grew significantly, which allowed the business to expand its activities during the yearly holiday surge season.

Options such as these show how much even moderate-size projects can gain from the incorporation of barcodes and QR codes.

Future Directions for Warehouse Automation with Barcode & and QR Code

Integration of barcodes and QR codes will continue to brighten and develop smoothly. Watch for these tendencies:

- RFID Integration: Combining QR/barcode scanning with RFID (Radio Frequency Identification) to enhance tracking and inventory control further.

- AI and Machine Learning: AI-driven WMS solutions could analyze data captured via barcode/QR code scanning to predict trends, optimize workflows, and reduce downtime.

- IoT Devices: More warehouses use IoT-enabled devices to create smart warehouses, where barcode-tagged items communicate directly with WMS for greater automation.

- Augmented Reality (AR): AR-enabled glasses for warehouse staff could display barcode-scanned data right in their field of vision, improving accuracy and speed.

Boost Warehouse Efficiency Now

For individuals hoping to keep pace in a rising, sophisticated logistics world, integrating QR code and barcode technology with warehouse management systems is necessary, but it is no longer an option. Using these resources helps you to streamline processes, change your operations, and guarantee quicker, more precise order fulfillment.

Ready to move your warehouse efficiency up to the next level? Then, start using barcode and QR code integration in your WMS.

Email Us

Email Us

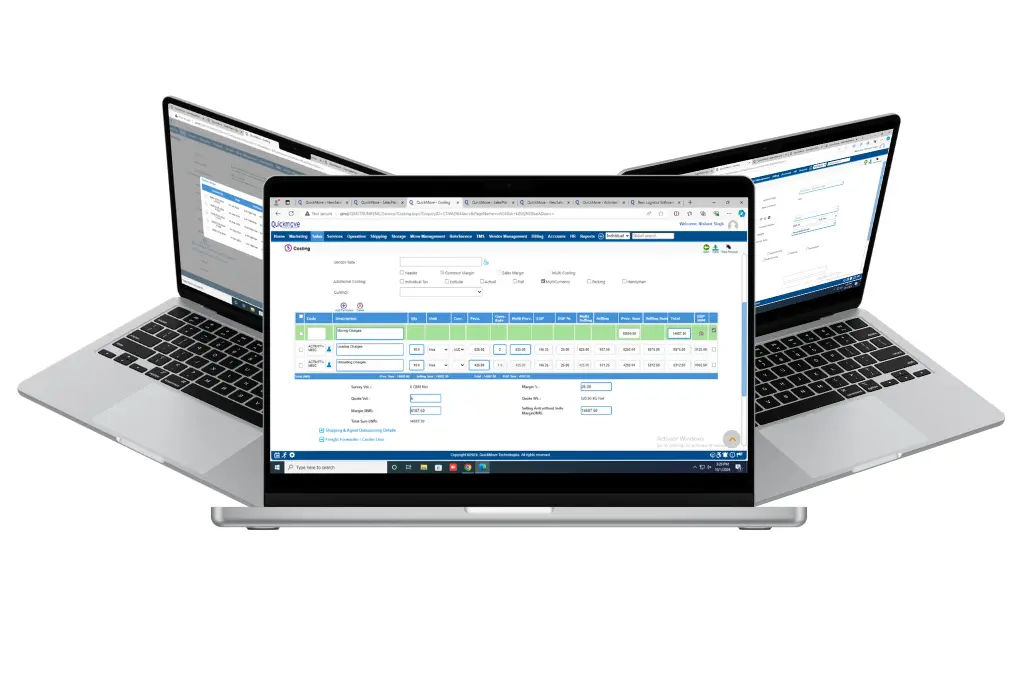

Freight Forwarding Software

Freight Forwarding Software Moving/Removal Software

Moving/Removal Software Warehouse Management System

Warehouse Management System Transport Management System

Transport Management System Customer Service Portal

Customer Service Portal Move Survey Quote Pro

Move Survey Quote Pro Digital Logistics Inventory App

Digital Logistics Inventory App